For businesses involved in print and paper goods, transitioning to an automatic shrink wrapper is a strategic investment in quality and efficiency.

|

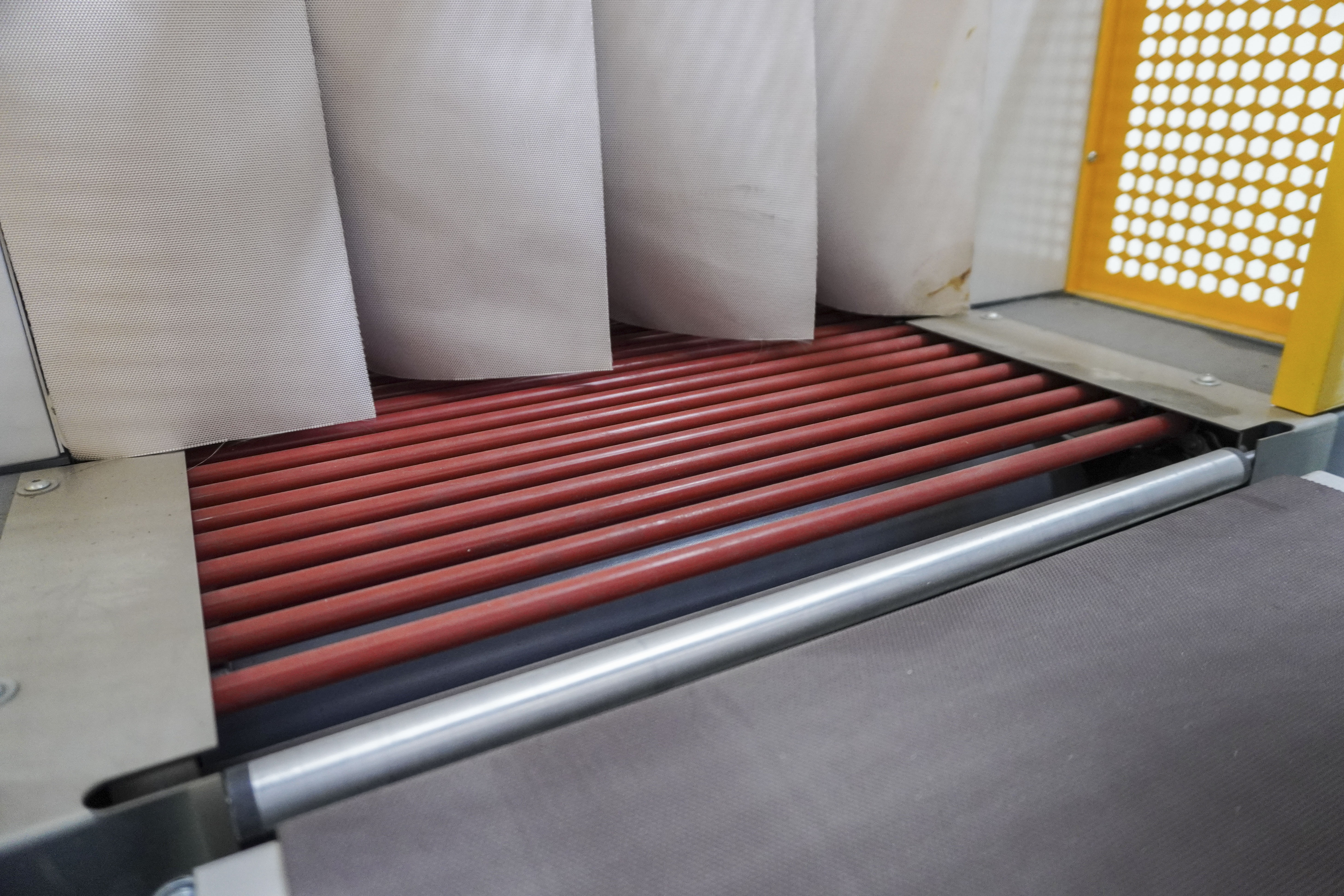

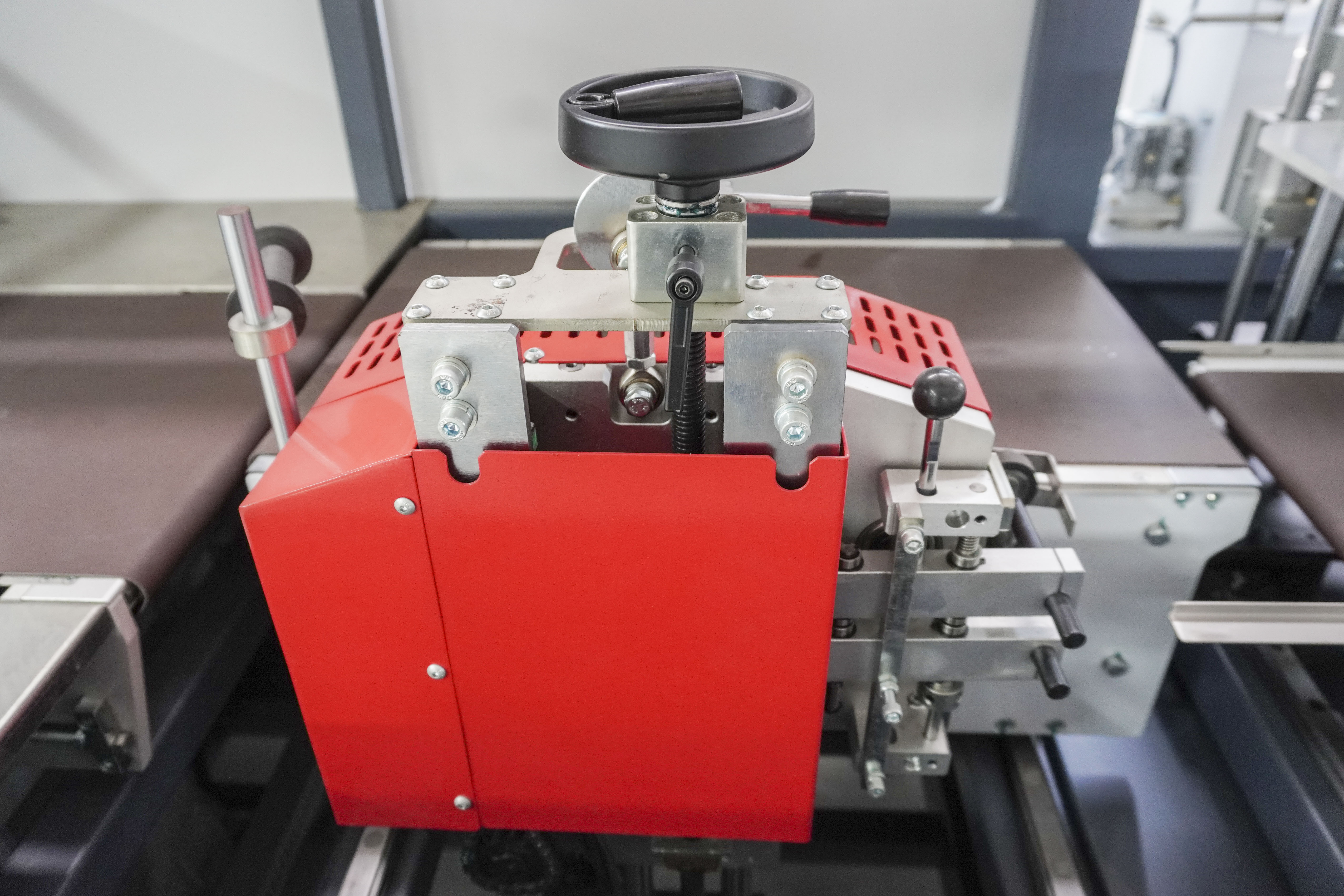

In the competitive world of publishing and stationery, protecting the final product is paramount. Shrink wrap machines offer an unparalleled solution, and specialized book shrink wrapping machines take this protection to a new level of precision and efficiency. Designed explicitly for the unique demands of book binding, these systems securely encapsulate hardcover books, paperbacks, wire bound notebooks, spiral bound journals, glued bound notepads, and diaries in a clear, protective polymer film. This automatic packaging process not only safeguards against scratches, moisture, and dust (dirt and debris) but also presents the product professionally, making it instantly retail-ready. The precision of a dedicated automatic shrink wrap machine for books starts with intelligent feeding and sizing. Equipped with both horizontal and vertical group electric eyes (sensors), the machine dynamically adjusts the cutting size automatically based on the book's orientation and dimensions fed from the automatic book loading unit. This is complemented by precise timer control. The automatic sealing and cutting unit is a marvel of engineering, featuring a Teflon coated constant temperature blade operating at a rapid transferring speed of 1m/sec. This combination ensures stable packing, cutting and sealing, delivering high quality seals with no adhesion and no breakage, crucial for maintaining the integrity of book covers and bindings.  Beyond the seal, the heat shrinking process is meticulously controlled. The machine incorporates an integrated heat controlling system within its heat circulating shrink stove (tunnel). The ability to freely adjust wind direction ensures consistent, uniform heat application around even irregularly shaped items like spiral bound books or hardcover volumes with dust jackets. Double layer insulation curtains enhance energy saving and maintain constant temperature, contributing to perfect, wrinkle-free shrinkage and a flawless, transparent display of the product. This thermal cycle technology guarantees the perfection of the plastic sealing effect.  Reliability is non-negotiable in high-volume production environments like packaging books & binding. These book packaging equipment are built for endurance. The electronic control part leverages components from globally renowned brands such as Panasonic, Omron, and IFM, ensuring equipment operation stability and a demonstrably low failure rate. Critical movements, like the horizontal knife, are driven by a powerful servo motor, providing unmatched precision and repeatability. This robust construction ensures the machine can handle the demands of continuous operation, wrapping thousands of books, notepads, or journals daily without missing a beat.  For businesses involved in print and paper goods, transitioning to an automatic shrink wrapper is a strategic investment in quality and efficiency. It saves labor significantly by automating a task traditionally prone to errors and fatigue. The high speed capability (up to 80 pieces per minute) eliminates bottlenecks in the finishing line. Most importantly, it delivers zero pollution packaging that keeps products immaculate. Whether preparing consumer products like CDs and DVDs alongside books or focusing solely on bound literature, this machine offers the high efficiency and low cost solution essential for thriving in today's market, transforming finished goods into protected, presentation-ready assets. |

| Tag:shrink wrapper,automatic shrink wrap machine,Shrink wrap machine |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!