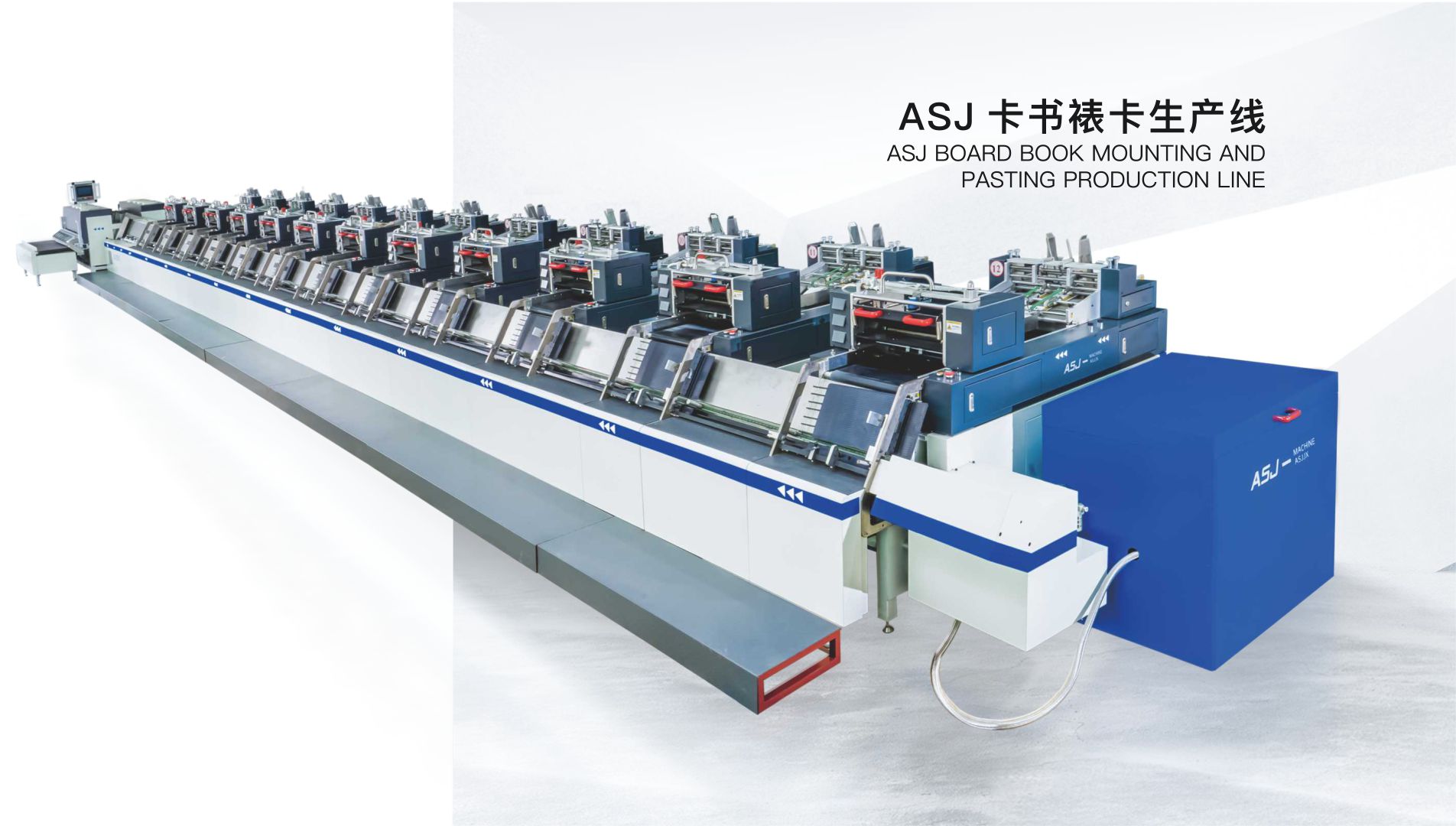

Board Book Pages Pasting and Glue Binding Line is designed for processing the book blocks of thick cartoon board books. It can handle cardboard within the range of 300gsm - 800gsm. Additionally, it can be customized to process various kinds of children's books such as lift-the-flap cartoon board books, peephole books, and classic board books according to different customer requirements.

HX480 Board Book Mounting and Pasting Production Line

The book production line is capable of performing the gluing and binding processes on the pre-die-cut and folded paper. The children's book production line consists of over ten sets of identical consoles. Each console can independently complete the glue application process on a single printed card paper. The pages are conveyed through the conveyor line, stuck together to form a book block, and finally pressed tightly by the bookbinding machine. The production speed is high, reaching up to 4200 copies per hour.

Features - Each console of the children's book production line is equipped with an automatic paper feeding device and an automatic gluing system. It can use stencil positioning and apply glue on special-shaped sheet paper as per customer demands.

- The children's book production line adopts servo motors, enabling automatic operation. It has the characteristics of low noise, easy operation, and high precision in positioning and mounting.

- The children's book production line utilizes a stencil gluing method, which can save glue. Moreover, the glue will not overflow, and the paper will not deform with this gluing method.

- The children's book production line is equipped with an alarm system that lights warning lights of different colors according to different conditions. Operators can promptly address problems by directly observing the colors of the warning lights. For instance, a red light indicates a lack of paper delivery, a yellow light signals a paper shortage before gluing, and a green light shows a normal condition.

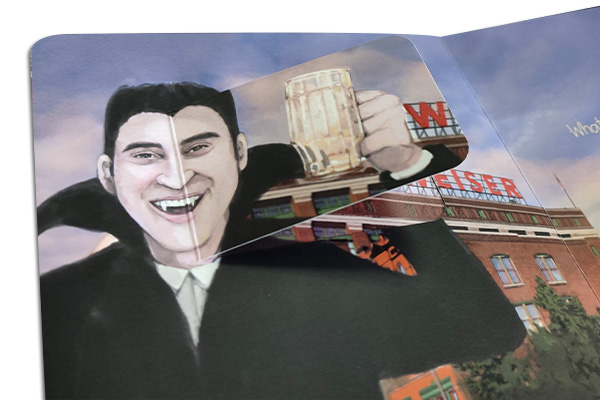

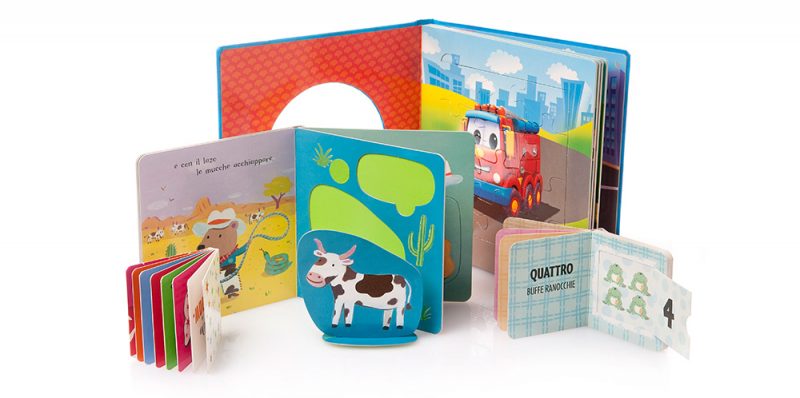

- Compared with the ordinary pasting machine, our shaped board book pages mounting & binding production line can not only achieve the comprehensive gluing of classic board books but also complete the partial gluing of opening pages, making the inner pages of books more diverse and filled with vivid images that children will love.

Comparison with Traditional Processing Method | Item | Traditional Processing Technology | Pop-up Book Card Pasting Production Line |

|---|

| Lift-the-flap book (12 tags) | 80 - 100 copies/h by 4 people | 2500 - 3600 copies/h by 5 people | | Puzzle book (12 tags) | 80 - 100 copies/h by 5 people | 2500 - 3600 copies/h by 5 people | | Peephole book (12 tags) | 800 copies/h by 5 people | 3600 copies/h by 5 people | | Classic board book (12 tags) | 1500 copies/h by 5 people | 3600 - 4000 copies/h by 5 people | | Pagination | Manual or machine gluing and page arranging | No page arranging required | | Pasting | Ordinary gluing machine | Free choice of gluing part |

HX480 Board Book Mounting and Pasting Production Line

Advantages - Gluing and Bonding Quality: Traditional Technology due to misalignment or irregular spines, the quality of each book varies.Board Book Pages Pasting & Glue Binding Line only need to input data, and after proper machine adjustment, the alignment precision of paper gluing is high.

- Ease of Glue Control: Traditional Technology is difficult to control gluing and thickness. The books may have inconsistent quality, be tackless, or get moldy. Board Book Pages Pasting & Glue Binding Line's gluing is uniform, and the amount of glue can be adjusted at any time according to paper requirements.

- Cost Reduction: Traditional Technology's basic requirement is that all workers should be skilled, which significantly increases the burden on enterprises. Board Book Pages Pasting & Glue Binding Line onlyneed one professional startup personnel is needed, and the other four can be ordinary employees.

|