This article discusses the impact of high-speed end sheet gluing machines on the bookbinding industry, highlighting their efficiency, consistency, and quality improvements.

|

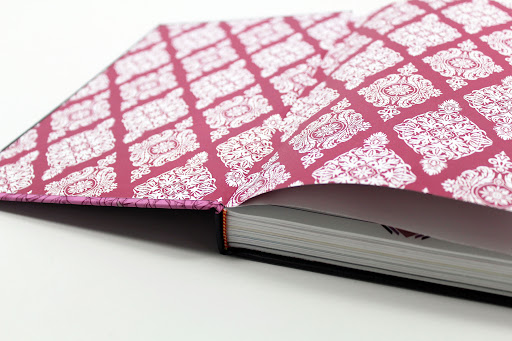

The bookbinding industry has seen a significant evolution over the years, with advancements in machinery leading to greater efficiency and higher quality products. One such innovation is the high-speed end sheet gluing machine. This powerful tool has revolutionized the way books are prepared for binding, allowing for faster production and more consistent results. Gone are the days of manual gluing, which was time-consuming and often led to inconsistencies. The high-speed end sheet gluing machine has automated this crucial step, streamlining the entire process and paving the way for greater output. These machines are designed to apply adhesive quickly and evenly to the end sheets of book blocks. This critical step ensures that the cover of the book will adhere securely, forming a durable and aesthetically pleasing product. High-speed end sheet gluing machines are particularly valuable in large-scale printing operations, where volume and speed are essential. The precision of these machines also leads to fewer errors and reduces waste, thereby decreasing production costs.  The advantages of using a high-speed end sheet gluing machine extend beyond just speed and consistency. These machines are also highly customizable, allowing adjustments for various book sizes and types of end sheets. This adaptability is crucial in a diverse printing environment where the dimensions and materials used can vary significantly. The ability to make these adjustments quickly and efficiently saves valuable time during setup, further contributing to the machine’s overall productivity.  In terms of functionality, the machine is equipped with sophisticated features that ensure optimal performance. These can include automated feeders, precise adhesive application systems, and advanced control panels that allow operators to monitor and adjust the settings as needed. The combination of high-speed operation and precise controls makes these machines an indispensable part of any modern bookbinding setup. Investing in such technology is not just about increasing production; it's also about improving the quality and longevity of the books being produced.  The integration of high-speed end sheet gluing machines into the production line marks a significant step forward for the bookbinding industry. These machines are not just tools; they are catalysts for efficiency, consistency, and improved quality. Their impact on large-scale book production is undeniable, and they will continue to play an essential role as the industry continues to evolve. The continuous refinement of this technology promises even greater improvements in the years to come, ensuring that books are produced with ever-increasing speed, precision, and durability. |

| Tag:High-Speed End Sheet Gluing Machine, Bookbinding Machinery, Automated Gluing Machine, End Paper Gluing Machine, Layflat Binding Machine |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!