The Anatomy of Accuracy: A Deep Dive into the Modern Paperboard Slitter

|

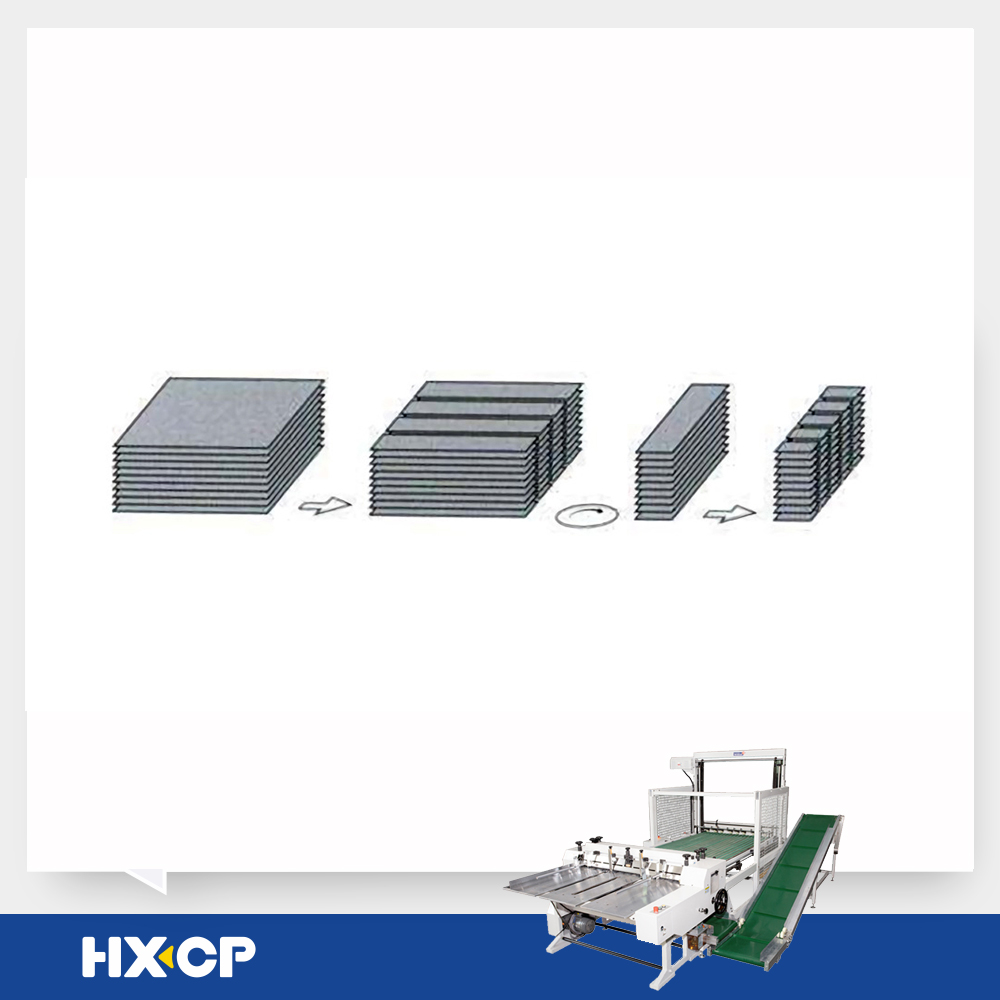

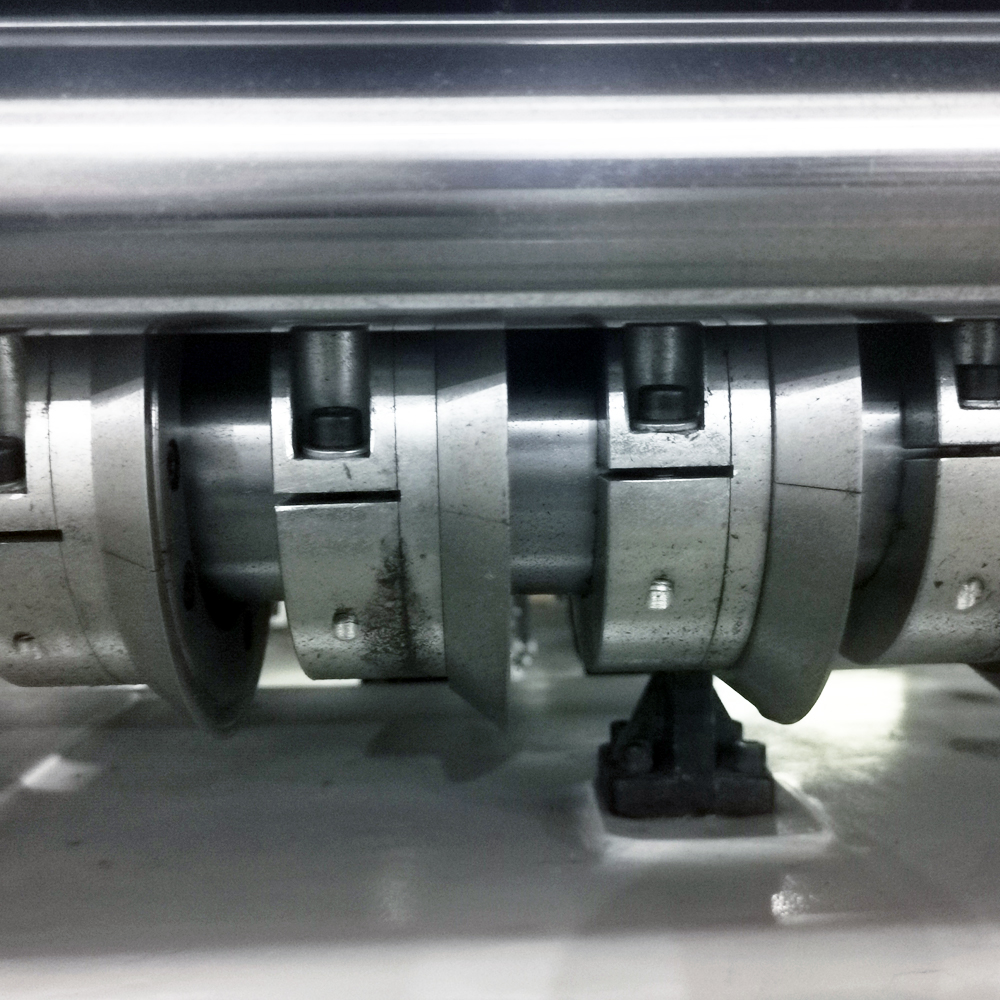

When it comes to cutting heavy book board and industrial cardboard, precision is everything. A flawless, smooth edge is the foundation of a premium product, whether it's a luxury case book cover or a durable color carton. This level of quality is achieved through the sophisticated technology integrated into a modern Paperboard Slitter. These machines are not just about cutting; they are about cutting perfectly every single time. Let's explore the key features that contribute to their exceptional accuracy and performance. At the heart of a high-end Paperboard Slitter is its advanced knife control system. Many top-tier models, such as the HX1200, are equipped with multiple pairs of individual slitter knives—often 7 couples (14 knives in total). What makes this system truly remarkable is that each knife is governed by its own dedicated servo system. This individual control allows for incredibly precise and independent positioning. An operator simply enters the required cutting parameters into a touch screen interface, and the servo motors move each knife to the exact coordinates with microscopic accuracy, ensuring every strip of cardboard is cut to the perfect width.  The feeding system is another critical component that directly impacts precision and workflow. A premier Paperboard Slitter Machine often features a versatile feeding mechanism. An automatic feeding system is ideal for high-volume, repetitive jobs, such as a second slitting pass, as it ensures a consistent and uninterrupted flow of material into the cutting unit. For larger or non-standard board sizes, the machine can be switched to a manual feeding mode. This dual capability provides the operational flexibility needed to handle any project, big or small, without sacrificing the machine's core precision.  The structural integrity of the machine cannot be overlooked. A "reasonable structure," as often described by manufacturers, refers to a robust and stable frame that minimizes vibrations during operation. Vibrations are the enemy of a clean cut. A well-built Paperboard Slitter is engineered to be heavy and rigid, ensuring the knives and the material remain perfectly aligned throughout the cutting process. This robust construction not only guarantees a smooth cutting edge but also contributes to the machine's longevity and reliability in demanding industrial environments.  Ultimately, the combination of servo-controlled knives, a flexible feeding system, a user-friendly touch screen interface, and a robust physical structure is what defines a top-quality Paperboard Slitter. It's this synergy of features that provides businesses with the power to produce high-accuracy work consistently and efficiently. When selecting a machine, looking closely at these technological elements will ensure you are investing in a tool that can truly elevate your production capabilities. |

| Tag:Paperboard Slitter,Paperboard,Paperboard Slitter Machine,Slitter |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!